Choosing the Right Solution for Commercial Refrigeration Repair in Toronto

Choosing the Right Solution for Commercial Refrigeration Repair in Toronto

Blog Article

Troubleshooting Commercial Refrigeration Repair Work: Strategies for Quick and Effective Fixes

Comprehending the common problems that plague business refrigeration systems and having a toolkit of diagnostic strategies at your disposal can make all the difference in swiftly determining and remedying issues. As we browse via the complexities of fixing commercial refrigeration fixing, we will discover the crucial techniques for fixing concerns successfully, guaranteeing that services can maintain optimal cooling efficiency and lessen downtime.

Common Commercial Refrigeration Problems

Business refrigeration systems typically come across a variety of operational concerns that can disrupt their efficiency and efficiency. One prevalent issue is inappropriate temperature level control, which can lead to food spoilage and waste if not promptly addressed.

Furthermore, cooling agent leakages position a considerable problem as they not just impact the cooling capacity of the system but also add to environmental injury. Identifying and fixing leakages immediately is important to avoid more damage and make sure conformity with regulations. Additionally, filthy condenser coils can hamper warm transfer, requiring the system to function harder and eat even more power. Normal cleansing and upkeep can help prevent this concern and prolong the lifespan of the refrigeration system.

Analysis Tools and Techniques

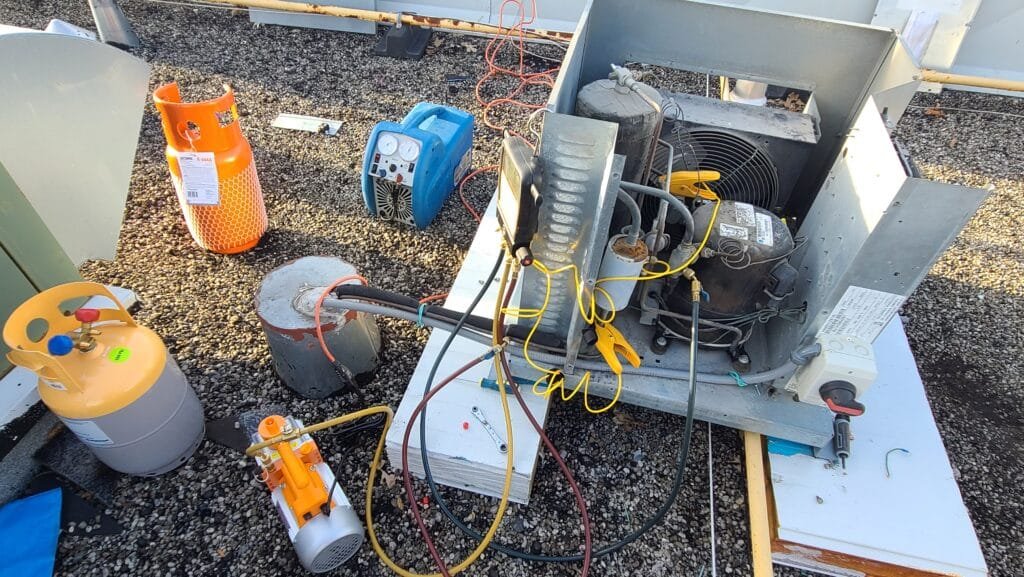

Effective troubleshooting of commercial refrigeration systems counts greatly on making use of specialized diagnostic devices and methods to recognize and deal with underlying concerns efficiently. One necessary analysis device is the multimeter, which assists professionals determine voltage, present, and resistance in different components such as compressors, electric motors, and thaw heaters. Thermostats are likewise crucial for assessing temperature differentials across the system to determine prospective troubles like refrigerant leakages or inappropriate airflow. In addition, leak discovery tools like electronic leak detectors or ultraviolet dye kits are vital for finding refrigerant leaks that can lead to system ineffectiveness.

Strategies such as stress testing using manifold assesses can establish if the system has the right refrigerant charge and determine any type of leakages. Visual assessments of elements for signs of wear, deterioration, or ice accumulation are likewise essential in diagnosing problems. Furthermore, information loggers can be employed to keep track of system efficiency in time and identify patterns that may indicate recurring problems. By incorporating these analysis devices and methods, professionals can properly fix industrial refrigeration systems and provide quick and specific repair work, lessening downtime and making sure optimum system efficiency.

Quick Repairs for Refrigeration Problems

When encountered with refrigeration problems, technicians can apply quick solutions to resolve usual issues promptly and efficiently. If the refrigeration unit is not cooling correctly, inspecting and readjusting the thermostat setups may offer a quick remedy prior to more in-depth troubleshooting is needed. By applying these quick fixes, professionals can attend to common refrigeration issues effectively and maintain commercial refrigeration systems running smoothly.

Preventative Maintenance Tips

Carrying out a proactive maintenance schedule is vital for making certain the longevity and optimum efficiency of industrial refrigeration systems. Normal maintenance not only assists protect against pricey malfunctions but likewise makes sure that the tools runs effectively, conserving energy and lowering general operating prices. Below are some preventative upkeep suggestions to keep commercial refrigeration systems running smoothly:

Check and Change Filters: Unclean filters can limit air flow, making the system job more difficult and potentially creating damages. Inspect and replace filters regularly to avoid concerns.

Inspect Seals and Gaskets: Dripping seals and gaskets can bring about temperature variations and energy wastefulness. Changing and evaluating damaged seals can assist maintain consistent temperatures.

Expert Assistance and Provider

To maintain the optimum performance attained through normal preventative maintenance, looking for specialist support and solutions for commercial refrigeration systems is essential. Expert technicians possess the competence and specialized expertise required to diagnose and attend to complicated problems efficiently. When dealing with tough refrigeration issues, relying on expert assistance can save both time and cash in the long run.

Expert solutions offer advantages such as accessibility to sophisticated tools and equipment, making certain that repair services are carried out properly. In addition, specialists are educated to follow industry laws and security criteria, decreasing the threat of accidents and guaranteeing conformity with legal requirements.

Verdict

In conclusion, fixing business refrigeration fixing needs a systematic technique to recognizing common issues, using analysis devices and techniques, carrying out quick repairs, and focusing on preventative maintenance. Expert assistance and solutions may be necessary for even more complex issues - Toronto webpage commercial refrigerator repair. By adhering to these techniques, organizations can ensure their refrigeration systems run successfully and effectively, reducing downtime and potential losses

Recognizing the common problems that pester business refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the distinction in quickly recognizing and treating troubles.Efficient troubleshooting of industrial refrigeration systems depends heavily on using specialized analysis devices and strategies to identify and deal with underlying problems effectively. By incorporating these diagnostic devices and methods, specialists can properly fix business refrigeration systems and provide exact and fast repair services, lessening downtime and making certain optimum system efficiency.

By executing these fast fixes, specialists can address usual refrigeration problems efficiently and maintain industrial refrigeration systems running smoothly.

Moreover, expert support can help expand the life expectancy of industrial refrigeration systems by determining possible problems before they rise.

Report this page